At Check-Mate, we work tirelessly to ensure consistently superior product quality. We have implemented an aggressive quality control program including SPC and our certified ISO 9001:2008 quality management system. We always have and always will strive for 100% customer satisfaction throughout the entire process. We accomplish this by consistently meeting our customers' requirements, keeping costs low through the practice of lean manufacturing, and continually improving our process in contract manufacturing.

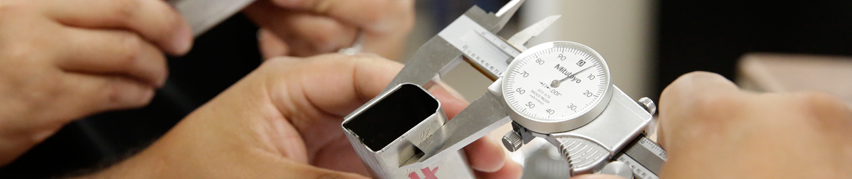

First, article inspection is performed for each new die or customer die that we refurbish. First piece inspection is performed at the start of each run in addition to in-line inspection during the run.

- Optical Inspection Services Available.

- Specializing in First Article.

- Performing of Capability Studies.

- All equipment traceable to N.I.S.T./N.B.S.

- Computer Generated Inspection reports also available.

Automated statistical process control (SPC) System is an integral part of our quality and inspection systems.

- Computer generated reporting.

- State-of- the art optical inspection equipment.

OGP smartscope optical inspections complete with QC- Calc SPC software with automated data collection for precise automated optical inspection are also available.

- Mitutoyo 14 optical comparators

- Micro- Vu digital optical comparator

For more information on our quality department and the inspection process for

Surgical Stamping, Metal Stamping and Assemblies, contact us.